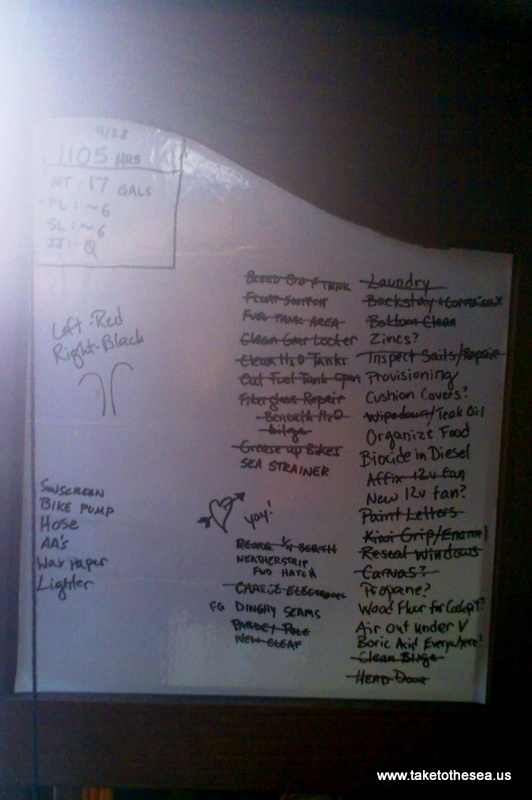

It grew. The boat list that is. Well, no…actually, the boat list itself remained the same size – our aspirations grew…and kept growing and dammit, we’re still working. I’m happy to report that we have had a ridiculously productive month. This month has actually been strangely reminiscent of last September, except in a foreign country and with temperatures cresting 95 degrees. Makes me miss (albeit briefly) the cool, foggy days in Ilwaco, WA where we repaired our keel smile and replaced the entire bow of our boat around the same time last year.

It grew. The boat list that is. Well, no…actually, the boat list itself remained the same size – our aspirations grew…and kept growing and dammit, we’re still working. I’m happy to report that we have had a ridiculously productive month. This month has actually been strangely reminiscent of last September, except in a foreign country and with temperatures cresting 95 degrees. Makes me miss (albeit briefly) the cool, foggy days in Ilwaco, WA where we repaired our keel smile and replaced the entire bow of our boat around the same time last year.  Way down our dream list this year was the idea to cut through the boat’s old original fuel tank and use the area for extra storage. The previous owner had abandoned the tank over six years ago because it was “too big” and “they never used the fuel before it went bad”. Harmony got out the jigsaw: this oughtta be easy.

Way down our dream list this year was the idea to cut through the boat’s old original fuel tank and use the area for extra storage. The previous owner had abandoned the tank over six years ago because it was “too big” and “they never used the fuel before it went bad”. Harmony got out the jigsaw: this oughtta be easy.  Wait. What is that? Is that FUEL? Has that been there the whole time? We thought it had a leak! Shoot, maybe we should put it back into service to double, DOUBLE! our capacity. First though we’d better clean out the old fuel — and deal with the fact that we just cut a big hole in a perfectly good steel tank . . .

Wait. What is that? Is that FUEL? Has that been there the whole time? We thought it had a leak! Shoot, maybe we should put it back into service to double, DOUBLE! our capacity. First though we’d better clean out the old fuel — and deal with the fact that we just cut a big hole in a perfectly good steel tank . . .  There was diesel all right – 50 liters of it (15 gallons for the gringos). For reference, that’s Harmony posing with the jug we FILLED using the tiny Jabsco pump featured in the picture above. A dirty job.

There was diesel all right – 50 liters of it (15 gallons for the gringos). For reference, that’s Harmony posing with the jug we FILLED using the tiny Jabsco pump featured in the picture above. A dirty job.  That amount of fuel is large enough and heavy enough to be a third crew member. Again…for six years! We always wondered why we had a list to starboard. Fortunately Marina Chiapas is able to find a use for all that old diesel.

That amount of fuel is large enough and heavy enough to be a third crew member. Again…for six years! We always wondered why we had a list to starboard. Fortunately Marina Chiapas is able to find a use for all that old diesel.  What do you do to cover a hole in a 35-gallon stainless steel tank that carries diesel fuel, often while heeled over at an angle? Use whatever’s at hand. In Chiapas Mexico, this consists of a piece of plywood, fiberglass, machine screws, goop, and hope.

What do you do to cover a hole in a 35-gallon stainless steel tank that carries diesel fuel, often while heeled over at an angle? Use whatever’s at hand. In Chiapas Mexico, this consists of a piece of plywood, fiberglass, machine screws, goop, and hope.  Jeff spent the entirety of a 94-degree day fashioning the tank repair, then half another day (not pictured) re-plumbing and bleeding the fuel lines to incorporate the new/old tank. He is happy to report that the new fuel system is as good as used.

Jeff spent the entirety of a 94-degree day fashioning the tank repair, then half another day (not pictured) re-plumbing and bleeding the fuel lines to incorporate the new/old tank. He is happy to report that the new fuel system is as good as used.  While Jeff was doing the fuel tank repair, Harmony went over to the neighbors’ “house” to do some sewing on their beloved SailRite machine. One rum and pineapple turned into four, and at 3pm she came back plastered , finished awning in hand, and proceeded to spend the next 2 hours “resting” on the dock. Jeff: “When we introduce this photograph, can we use the phrase “Stinking Drunk” to describe you?”

While Jeff was doing the fuel tank repair, Harmony went over to the neighbors’ “house” to do some sewing on their beloved SailRite machine. One rum and pineapple turned into four, and at 3pm she came back plastered , finished awning in hand, and proceeded to spend the next 2 hours “resting” on the dock. Jeff: “When we introduce this photograph, can we use the phrase “Stinking Drunk” to describe you?”  The product of her labor. It will eventually double function as both an awning and a rain catchment system. One of those pieces was accidentally sewn upside down – that was after the third Pineapple and Rum.

The product of her labor. It will eventually double function as both an awning and a rain catchment system. One of those pieces was accidentally sewn upside down – that was after the third Pineapple and Rum.  Another item on our dream list was to uncover a timber that had been “weeping” to see if there was any water damage in the hull. We found that water had somehow been trapped between the fiberglass and hull, though fortunately there was no rot. The working theory is that the limber holes (where the hoses run through the floor timbers) weren’t properly sealed with epoxy, plus the water tank area (which sits directly on the timber) hadn’t been sealed either. After several days exposed in the Mexican heat and a few mornings with the heat gun in our underwear, the hull was once again bone dry.

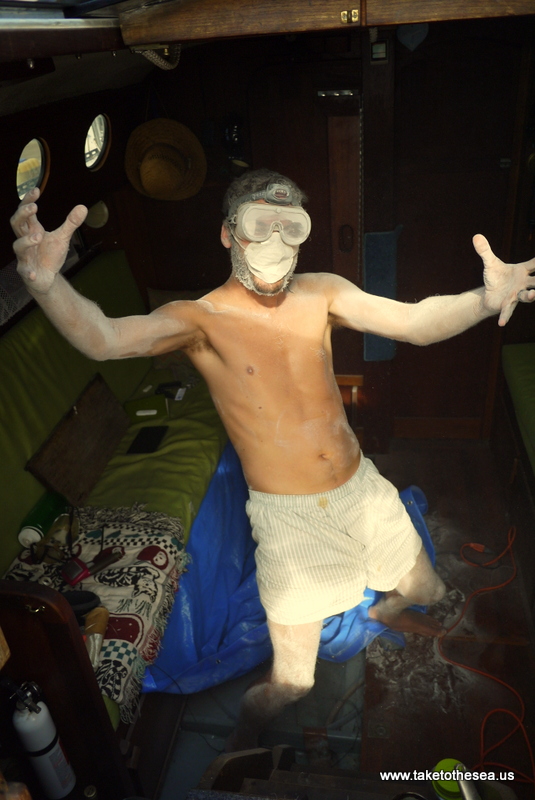

Another item on our dream list was to uncover a timber that had been “weeping” to see if there was any water damage in the hull. We found that water had somehow been trapped between the fiberglass and hull, though fortunately there was no rot. The working theory is that the limber holes (where the hoses run through the floor timbers) weren’t properly sealed with epoxy, plus the water tank area (which sits directly on the timber) hadn’t been sealed either. After several days exposed in the Mexican heat and a few mornings with the heat gun in our underwear, the hull was once again bone dry.  Jeff’s workshop. To prepare for the fiberglass repair, Jeff had to do some grinding. For those of you that are not acquainted with fiberglass dust, it’s probably the most pernicious element on the face of the earth. The tarp helped to protect the interior, but even so, most things were covered in a fine layer. – Jeff: “Don’t knock my work coccoon.”

Jeff’s workshop. To prepare for the fiberglass repair, Jeff had to do some grinding. For those of you that are not acquainted with fiberglass dust, it’s probably the most pernicious element on the face of the earth. The tarp helped to protect the interior, but even so, most things were covered in a fine layer. – Jeff: “Don’t knock my work coccoon.”  It emerges.

It emerges.

I am a monster!

I am a monster!  But really, I have fiberglass on my balls. Time for a shower.

But really, I have fiberglass on my balls. Time for a shower.  The repair.

The repair.  Still the repair.

Still the repair.  You know it’s been a hard day of working when goggles show up in the “to be washed” pile with all of the dirty dishes that have accumulated.

You know it’s been a hard day of working when goggles show up in the “to be washed” pile with all of the dirty dishes that have accumulated.  Harmony’s homemade solar food dehydrator with the first experimental mango.

Harmony’s homemade solar food dehydrator with the first experimental mango.  The boat projects were done, for about the third time. We were getting ready to shove off on Monday and finally head for El Salvador. The boat had been clean for at least two days. Life was simple. Then Harmony decided to go to the dentist, and all of a sudden we had another week in Chiapas. Jeff started to get bored. What to do? Let’s start on the dinghy project list! First up: fiberglassing the center seam to hopefully finally stop the leaks.

The boat projects were done, for about the third time. We were getting ready to shove off on Monday and finally head for El Salvador. The boat had been clean for at least two days. Life was simple. Then Harmony decided to go to the dentist, and all of a sudden we had another week in Chiapas. Jeff started to get bored. What to do? Let’s start on the dinghy project list! First up: fiberglassing the center seam to hopefully finally stop the leaks.

Looks awesome, y’all! Great job(s)!

ps. I’ve totally ended a sewing project on the dock like that! What is it with seamstress-mentors and their pushy batenders!?! . . . twist my arm 😉

Glad to hear I’m not the only one. I thought I had it totally under control until I started the walk back to our boat. I’m lucky I made it all the way back to our finger.